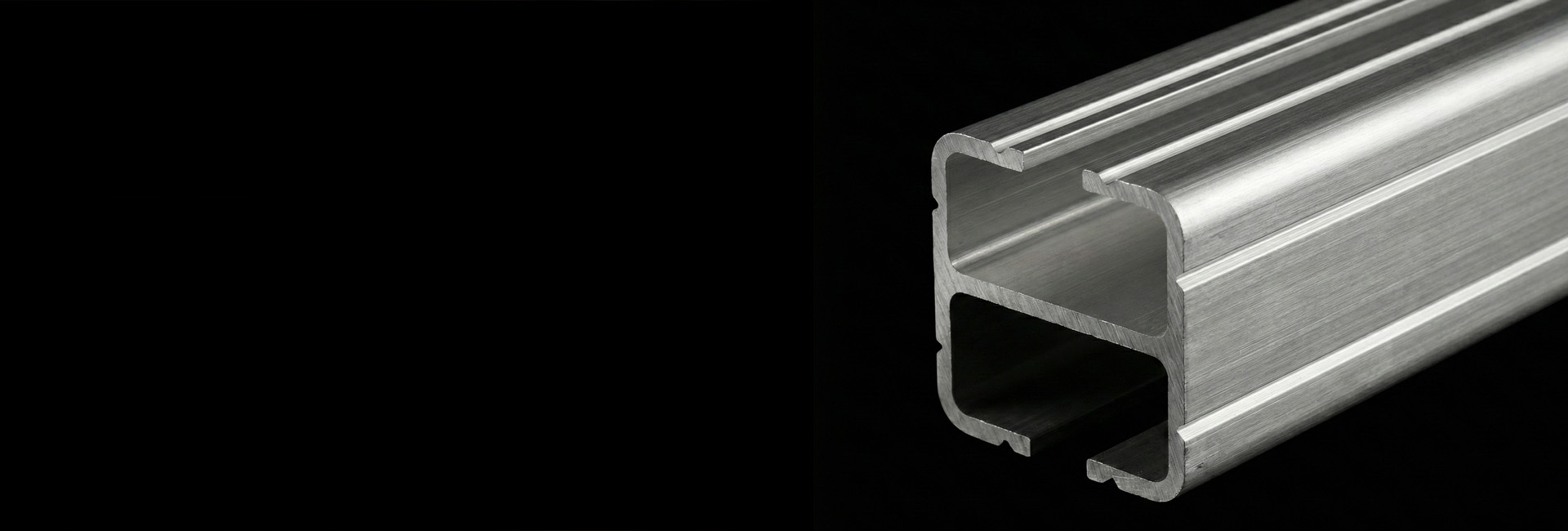

Integral Web Bus Conductor (IWBC)

Maximum Structural Rigidity for High-Current Substations

Engineered for the demands of modern power distribution, Maverick Metals’ Integral Web Bus Conductor (IWBC) combines exceptional mechanical strength with high-efficiency current ratings. Unlike standard tubular bus, the IWBC features a unique internal web design that reinforces the profile, allowing for longer spans and higher fault-current withstand capabilities without the need for external stiffeners.

Designed to streamline substation architecture, our IWBC eliminates the need for complex spacing components like clamps or welded tie bars, reducing installation time and total system weight while maximizing airflow for natural cooling.

Aluminum Alloy Options

We supply IWBC in high-conductivity and structural aluminum grades to match your specific project requirements.

6061-T6: A structural grade utilized when mechanical strength is the primary priority over maximum conductivity.

6101-T6 (Standard Electrical): The industry standard for bus conductors. It offers the optimal balance of high electrical conductivity (approx. 57% IACS) and mechanical strength.

6063-T6: Known for excellent corrosion resistance and surface finish, often used in exposed outdoor environments.

IWBC Dimensions & Weights

Specifications

| Size (Inches) |

Wall Thickness (Inches) |

Area (sq in) |

Weight (lb/ft) |

|

|---|---|---|---|---|

| Height (A) | Width (B) | T | ||

| 4 | 4 | 0.156 | 2.439 | 2.87 |

| 4 | 4 | 0.250 | 3.781 | 4.45 |

| 4 | 4 | 0.312 | 4.460 | 5.25 |

| 6 | 4 | 0.250 | 4.780 | 5.62 |

| 6 | 4 | 0.375 | 6.020 | 7.10 |

| 6 | 4 | 0.375 | 6.950 | 8.17 |

| 6 | 5 | 0.375 | 7.600 | 8.94 |

| 6 | 6 | 0.375 | 8.600 | 10.15 |

| 6 | 6 | 0.550 | 11.220 | 13.19 |

| 7 | 7 | 0.500 | 12.840 | 15.10 |

| 8 | 5 | 0.375 | 9.080 | 10.68 |

| 8 | 5 | 0.500 | 11.750 | 13.82 |

| 8 | 8 | 0.500 | 16.120 | 18.96 |

| 9 | 9 | 0.625 | 20.040 | 23.57 |

| 10 | 10 | 0.625 | 23.500 | 27.64 |

Industries & Applications

The Backbone of High-Voltage Distribution

Grid Modernization: Retrofitting older copper systems with lightweight, high-efficiency aluminum IWBC to reduce structural load.

High-Voltage Substations: Primary bus runs where long spans and fault-current rigidity are required.

Switchyards: Main connections between transformers and breakers.

Heavy Industrial Plants: Distribution feeds for aluminum smelters, chemical plants, and data centers requiring massive amperage capacity.

Engineered for the Grid. Delivered for the Project.

Turnkey Supply: We don’t just supply the bar; we can assist with connector selection and logistics for large-scale utility projects.

Custom Fabrication: Need holes, slots, or miters? Our CNC machining capabilities ensure your IWBC arrives ready for installation.

Speed to Site: With stocking locations across the US, we minimize lead times for critical infrastructure upgrades.

Quality You Can Trust

You can count on our superior metal solutions for on-time performance and dependable materials. We deliver quality you can trust, ensuring durability and seamless integration into your projects.

What People Say

“The customer service you provide is impeccable, and I truly believe that this is what is going to set Maverick apart from anyone else in the industry. We are excited about this partnership and know that Maverick will play a huge part in our success.”

Daniel Vass

Purchasing, Active Customer

Ready to engineer your next power distribution system?

Contact our sales engineers now for a custom quote on IWBC, tailored dimensions, profiles, and alloys to fit your exact specifications. We offer industry-leading turnaround times, competitive pricing, and direct mill allocations to benefit our customers.