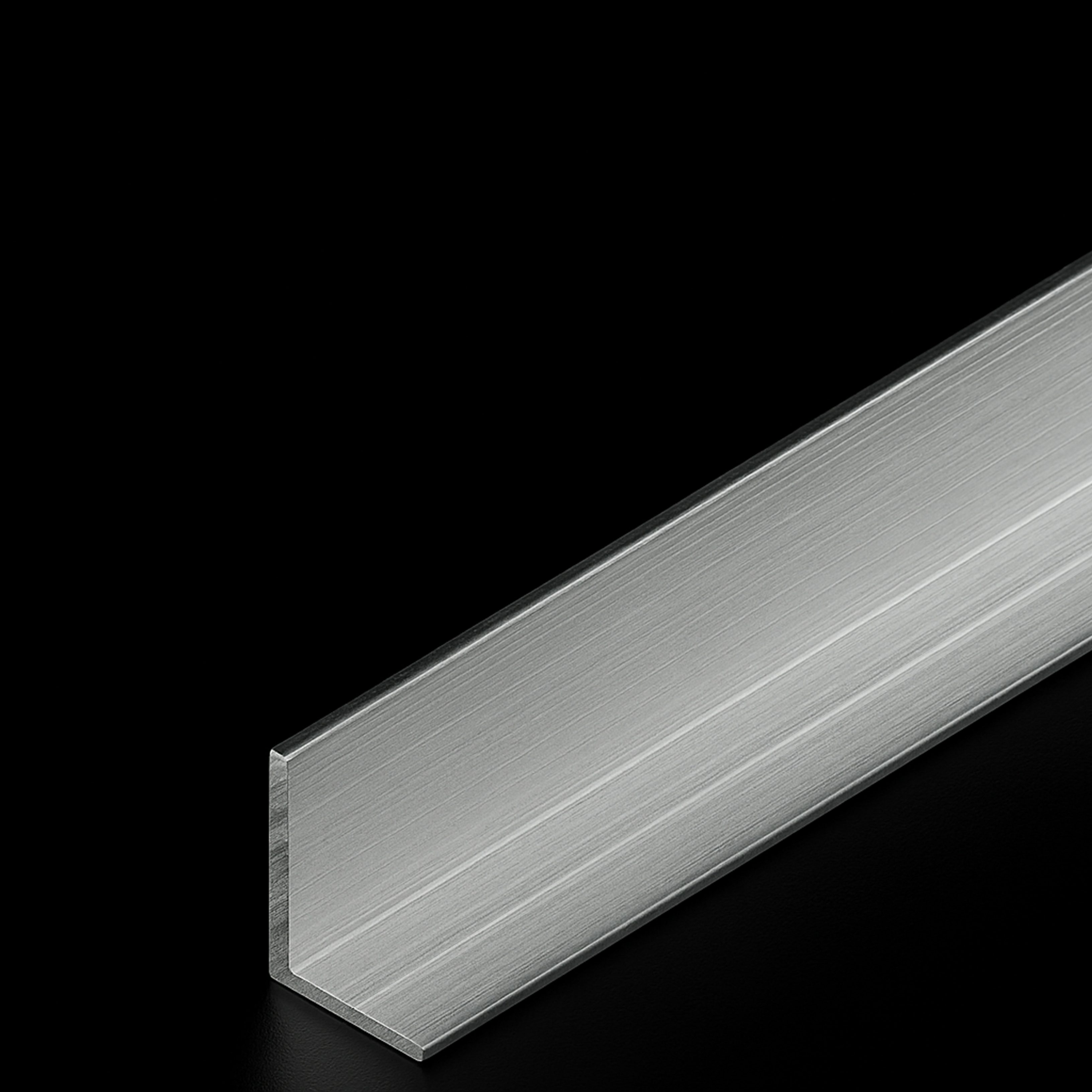

Universal Angle Bus Conductor (UABC)

High-Performance Aluminum Bus for Flexible Outdoor Power Connections

The Universal Angle Bus Conductor (UABC) is an extruded aluminum angle designed for use in medium-voltage power distribution systems, especially in outdoor substation environments. Engineered for strength, conductivity, and installation flexibility, UABCs provide a reliable and adaptable method of interconnecting equipment and bus structures.

Key Features & Specifications

Each conductor features a right-angle profile with precision-machined centerline notches on both legs, enabling fast, accurate bolt alignment without the need for field measuring or additional templates. The uniform wall thickness of both legs allows for straightforward mounting on insulator caps or directly onto structural supports.

Unlike traditional flat or custom-bent busbars, UABCs streamline assembly by reducing the number of fittings or transition pieces required, helping contractors and utilities save on labor and hardware. The angle configuration supports robust mechanical integrity while maintaining excellent electrical performance.

Alloy: High-conductivity 6101 aluminum, heat-treated to T6, T61, or T63 temper

Design: Uniform leg thickness with centerline notching for precise bolt placement

Application: Mounts directly on insulators or with terminal connectors

Sizes Available: From 3¼” to 5″ width with wall thickness of ¼” or ⅜”

Common Uses: Substations, utility-grade installations, industrial panels

UABC Dimensions & Weights

Specifications

| Size (W x T) | Notch A | Notch B | Notch C | Notch D | Area (in²) | Weight (lb/ft) |

| 3¼” × ¼” | 1.500 | 1.750 | — | 2.375 | 1.57 | 1.83 |

| 4″ × ¼” | 1.875 | 1.750 | 2.000 | 2.813 | 1.93 | 2.27 |

| 4″ × 3/8″ | 1.875 | 1.750 | 2.000 | 2.813 | 2.85 | 3.36 |

| 4½” × ⅜” | 2.187 | 1.750 | 2.000 | 3.006 | 3.23 | 3.80 |

| 5″ × ⅜” | 2.313 | 1.750 | 2.000 | 3.256 | 3.60 | 4.24 |

Industries & Applications

UABCs are extruded from 6101 aluminum, a material well known for combining high conductivity with structural durability. Multiple wall thicknesses, widths, and temper options are available to match the thermal and electrical demands of your system. Configurations are compatible with bolted connectors or terminal lugs for tap-offs and expansion flexibility.

Electrical Power Distribution (substations, bus ducts, switchboards)

Power Generation Systems (plants, generators, transformers)

Electrical Panels & Switchgear (control cabinets, breaker assemblies)

Renewable Energy (solar combiner panels, wind systems, battery storage)

Data Centers & Critical Infrastructure (busway feeders, UPS connections)

Rail, Marine & Heavy-Industrial Systems (locomotives, shipboard electrification, motor controls)

Reliable Infrastructure Solutions

Upgrade your substation and electrical infrastructure demands with our high-quality aluminum bus pipe. Our premium pipe can help you to efficiently reduce maintenance needs.

Quality You Can Trust

You can count on our superior metal solutions for on-time performance and dependable materials. We deliver quality you can trust, ensuring durability and seamless integration into your projects.

What People Say

“The customer service you provide is impeccable, and I truly believe that this is what is going to set Maverick apart from anyone else in the industry. We are excited about this partnership and know that Maverick will play a huge part in our success.”

Daniel Vass

Purchasing, Active Customer

Ready to engineer your next power distribution system?

Contact our sales engineers now for a custom quote on aluminum coil —tailored dimensions, profiles, and alloys to fit your exact specifications. We offer industry-leading turnaround times, competitive pricing, and direct mill allocations to benefit our customers.